Top Views

Featured Views

Always Ready

Building a Bridge

Building a bridge over the Cohocton River in Corning NY. Our 500-ton crane lifted ten 100’ pre-stressed concrete beams weighing 110k lbs. across two spans. This was completed by building a causeway to the middle pier and being able to lift all the beams from a single setup without needing a slider beam.

Bonus question- What shape is the beam?

Building a Bridge

Building a bridge over the Cohocton River in Corning NY. Our 500-ton crane lifted ten 100’ pre-stressed concrete beams weighing 110k lbs. across two spans. This was completed by building a causeway to the middle pier and being able to lift all the beams from a single setup without needing a slider beam.

Bonus question- What shape is the beam?

Water storage Tank

Constructing a water storage tank with tilt up pre cast concrete panels. Our 350-ton crane lifted each panel weighing 60k lbs. from a horizontal bed and rotated vertical using both hoists on the crane then setup into position where each panel is supported by bracing. After completing three quarters of the tank the crane will move to the outside perimeter and finish installing the final panels.

Top Views

Compressor Stations in Appalachian Basin

Building new compressor stations in the Appalachian Basin has its own set of logistics. Mansfield Crane Service meets these demands with equipment and experience to do the job correctly and ahead of schedule.

Winter Work

Winter in Pennsylvania and New York is here. With snow and cold comes additional precautions and planning. Mansfield Crane Service continues to provide service by adapting to changes in conditions. Accessing remote telecom sites through the region is our specialty.

Midstream in the Appalachian Basin

With the redeploying of compressors midstream in the Appalachian Basin, Mansfield Crane Service showed our ability to rig these into buildings without roof removal in less than 4 hours. This saves a significant amount of money and time.

Yards in Pennsylvania and New York

Part of Mansfield Crane Service offerings to our customers are various yards in Pennsylvania, New York, and the Appalachian Basin. These yards can be used as staging for projects. This creates a time buffer that allows components to be delivered as...

Hanging Commercial Construction Iron

Hanging iron for commercial building construction entails sorting (shaking) out steel columns, girders, and joists on the ground. Once this is done, the pieces are then lifted into place piece-by-piece. Mansfield Crane Service operators keep a...

Civil Construction – Always Ready

Heavy civil construction with inherent tight schedules and changes in conditions. Mansfield Crane Service meets these demands with a team that is “Always Ready”. We received the initial call for this project at 5pm and we had a 500-ton crane setup...

HVAC- Always Ready, Even On Weekends

HVAC work on rooftops often requires reaching out long distances and usually deploying during the weekend.

Mansfield Crane Service handles both of these obstacles effortlessly for our customers to swap RTUs and get up and running before the start of the work week.

Ready To Handle Your Telecom Projects

Telecom projects in Pennsylvania and Upstate New York are challenging with specific job requirements.

Mansfield Crane Service is your end-to-end single source for crane and ancillary services for these projects.

Midstream Appalachin Basin

Midstream in the Appalachian Basin consists of projects that demand a high standard of performance.

Mansfield Crane Service meets these challenges with a deep understanding of the industry allowing us to execute plans correctly and safely while adjusting for changes in schedule and site conditions.

Quick Dispatch

Having the ability to plan and dispatch cranes quickly gives our customers time back on their schedules.

Keeping the industrial engine of production up and running is where Mansfield Crane Service’s motto of “Always Ready” comes into play. When you need us, we’ll be there with the knowledge and equipment you need.

Box Culvert Placement

Reaching out to set the wing section of a box culvert.

Mansfield Crane Service’s 500-ton crane lifted 22 sections weighing up to 80k lbs. a piece.

Water Tank Assembly

Our team at Mansfield Crane Service recently had a part in building a 4-million gallon water tank. Our 350-ton crane meticulously lifted pre-cast wall and roof panels piece-by-piece, just like building a giant puzzle.

Relocating Compressors

Mansfield Crane Service is your expert when it comes to Midstream in the Appalachian Basin. Our 500-ton cranes are the perfect piece of equipment for relocating compressors.

Single Source For Telecom Industry in PA and NY

Mansfield Crane handles everything for the telecom industry in house. From contracts, to safety road closures, permitting, and lift planning; our team handles the entire process so you don’t have to.

Building Bridges

Sometimes there’s nothing better when you’re in the crane business than building a bridge in the summertime. We recently worked on a couple of big bridge projects.

Well Work In The Appalachian Basin

For well work with coil tubing Mansfield Crane Service covers the entire Appalachian Basin with cranes and crews to run 24/7.

Telecom Installation Logistics

Sometimes our projects require us to close roads. This is especially true for telecom installations on rooftops to make sure everyone involved and around the area stay safe.

Congratulations to Sam!

Congratulations to our own Sam Cavanaugh for adding Board Certified Associate Safety Professional to his resume.

The team at Mansfield Crane is always working to move up with their development. We’re very proud of Sam for his recent certification.

Transport Services

In the Appalachian Basin Mansfield Crane Service brings a seamless solution for relocating equipment from well sites, compressor stations, and storage yards.

Always ReadY Day or Night

Turning right by night. Mansfield Crane Service recently completed a safe and efficient rig move in the Appalachian Basis.

This project entailed rigging down and relocating 180 miles with the West Penn Energy Services, LLC.

Appalachia Spring Social

Mansfield Crane Service is proud to sponsor the Oilfield Helping Hands (OHH) 2025.

The Appalachia Spring Social is May 29, 2025 in Williamsport, PA. The event is allowing the group to grow its presence in the region for the third year. The Appalachia Chapter is OHH is eager to host this fantastic evening.

As a sponsor we’re honored to support OHH’s mission of helping oilfield families in financial crisis.

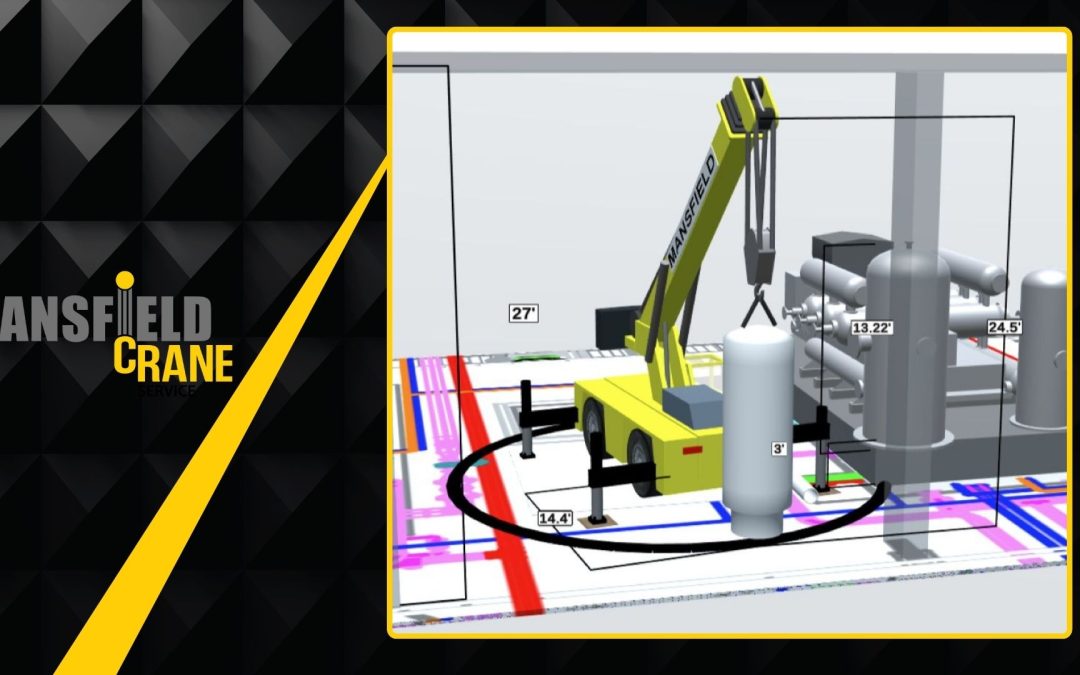

Always Prepared

We bring rigging to every job making sure we are always prepared for your project. This 170k lbs compressor skid had an offset CG requiring adjustment to sling length to level out. It may look simple however, 47 individual components of rigging equipment were needed to be planned and deployed. At Mansfield Crane, we created our own system to manage this effectively to keep pace with our schedule.

Wind Turbine Maintenance

Ever look up at those giant wind turbines and wonder how they get repaired when needed?

When you involve Mansfield Crane on the job we can tell you that it gets done a lot easier than without us.

Billboard Install

When it comes to installing a welcome sign for our new neighbor in Mansfield, PA, Mansfield Crane knows how to do it right!

Natural Gas and The Appalachian Basin

Midstream in the Appalachian Basin is all about uptime and at Mansfield Crane Service we work hard to assist our customers in pushing natural gas.

We recently used our 350-ton crane to remove a 3516 compressor for an upgrade to a larger unit.

Electrical Substation Work

At Mansfield Crane Service we recently used our 350-ton crane to lift a 150k lbs. transformer onto a pad for an electrical substation expansion in central Pennsylvania.

We always support the build out of infrastructure throughout our state to meet the ever growing needs in the area.

Night Work

We recently had the opportunity to work in the moonlit night to stack an exhaust stack.

We used our 165-ton crane to lift sections of a new system, while our 55-ton, 25-ton, and a spider crane built ducting during a shutdown.

Decades Of Experience

Mansfield Crane Service has decades of experience serving our customers in the Appalachian Basin, an area that contains the Marcellus/Utica play.

We give special attention to the production phase when natural gas leaves the well head and enters the process of cleaning and dehydrating before compression.

Working In Small Spaces

Since Punxsutawney Phil said six more weeks of winter, we decided to stay indoors.

Mansfield Crane Service was in charge of changing out equipment in a sawmill with our compact 25-ton crane.

Even our smallest crane comes standard with our own rigger to ensure that work is done by a qualified person. This premier level of service is what our customers deserve.

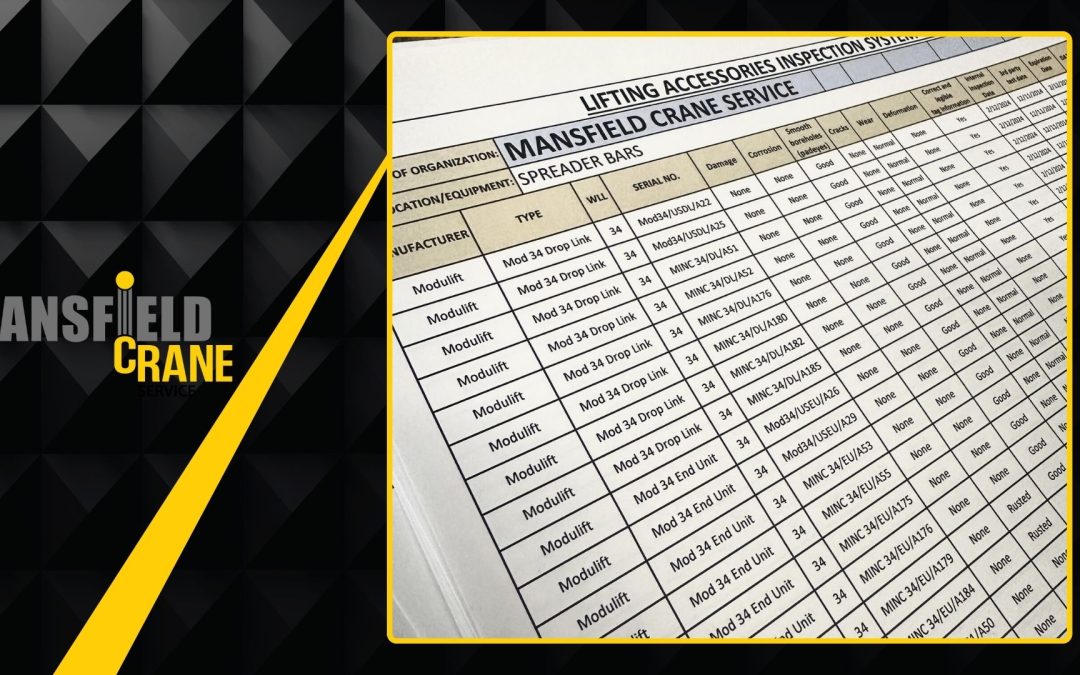

Equipment Inspection Time

At Mansfield Crane we take inspecting our equipment very seriously as it affects the safety of our crew and our worksites. Every year we take on the monumental internal task of Rigging Equipment Inspections.

Our inspections include carefully examining over 3,000 individual pieces of mostly below-the-hook components. These components include shackles, slings, and spreader bars, as well as additional items. For each piece we check every weld, link, and strand.

Chain slings receive more scrutiny as they are returned to the manufacturer for a thorough inspection and test.

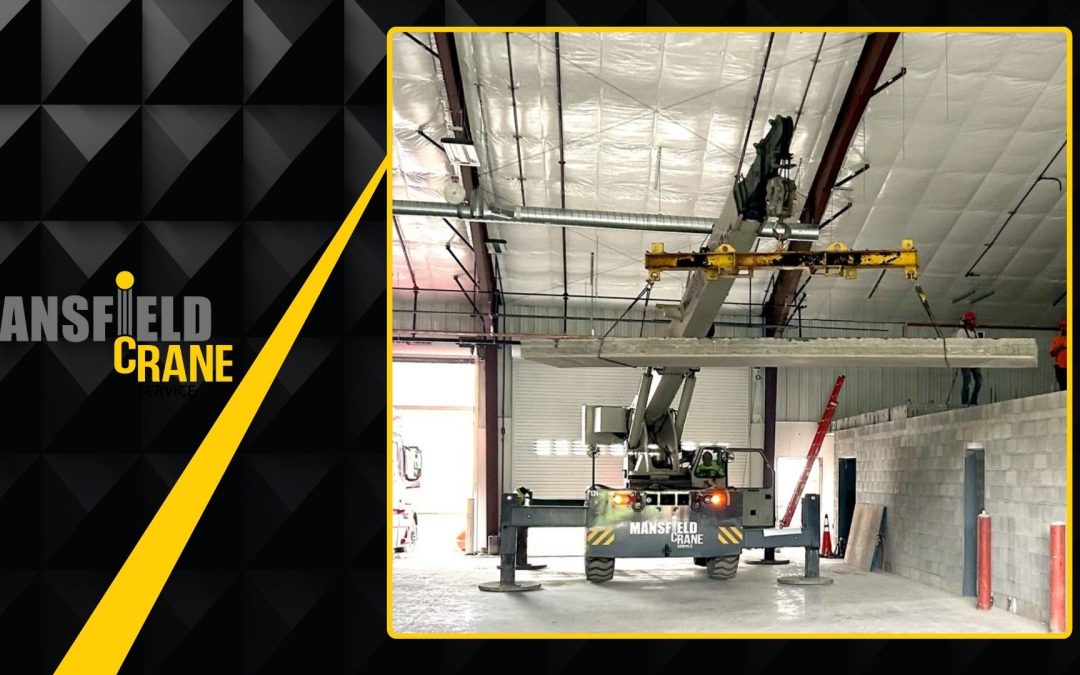

Working Inside

During the cold winter months we are especially happy to work on interior jobs. We recently worked on a project replacing a vibratory conveyer for an industrial customer that needed a solution to reach over existing conveyor lines during a shutdown.

We were able to complete this job with ease with our team of operators and riggers using a compact 115-ton crane with all wheel steering. Our top of the line equipment made its way through the factory where it was able to set up and accomplish the job.

Working with Barnhart

Mansfield Crane Service enjoyed our recent work with Barnhart Crane and Rigging and their MOCCS horizontal cantilever. With their collaboration we were able to reach inside a compressor building and remove a motor.

Mansfield Crane Service is Always Ready

There are over 8,760 hours in a year and Mansfield Crane Service is “Always Ready” to get to work on your project.

For this job we were asked to work on snubbing and coil tubing in the Appalachian Basin, not a problem when you’re working with Mansfield Crane Service.

Lifting HVAC equipment

We took advantage of Thanksgiving break at a local school to lift new HVAC equipment onto their rooftop.

Our 500-ton crane reached out 230’ with 20k pounds to replace the units with ease.

This crane’s mobility and strength gives our customers an advantage in completing projects with narrow time frames.

Beer & Boots Podcast

Thank you to the Beer & Boots Podcast for this fantastic bobble head of the owner of Mansfield Crane Service, Trapper Wyman. Trapper considers this the pinnacle of his success, well this and creating and running a successful crane business.

Lifting bridge panels

Lifting bridge panels looks easy with our experienced team and our 350-ton crane. Mansfield Crane Service loaded the bridge panels from a storage yard and then placed them on location in Upstate New York.

Structural Steel Removal

Mansfield Crane was recently approached to work on an airplane hanger to remove structural steel partitions using our 25-ton and 55-ton cranes and transport the material offsite.

Cell Tower Site installations

Cell Tower Site installations always come with their own set of challenges when it comes to accessing the install location and setup. Mansfield Crane Service has invested in equipment to reach even the most remote locations throughout Pennsylvania and Upstate New York.

Building A Bridge

Building a bridge over the Cohocton River in Corning NY. Our 500-ton crane lifted ten 100’ pre-stressed concrete beams weighing 110k lbs. across two spans. This was completed by building a causeway to the middle pier and being able to lift all the...

Water storage Tank

Constructing a water storage tank with tilt up pre cast concrete panels. Our 350-ton crane lifted each panel weighing 60k lbs. from a horizontal bed and rotated vertical using both hoists on the crane then setup into position where each panel is...

setting up a monument to John W. Jones

This unique job was setting up a monument to John W. Jones, an Elmira, NY resident who escaped slavery and was instrumental in the Underground Railroad. After reading about his life’s history I am impressed by his compassion for the people he...

setting up inside the fence of the tower site

Planning a flawless execution on this cell tower extension with Mansfield Crane Service being able to setup inside the fence of the tower site. This saved extensive time and money that would have been needed for matting to setup on a slope. Even...

Announcing the addition of

We are always pleased to announce new equipment. Announcing the addition of a Liebherr LTM 1400 500- ton class crane to Mansfield Crane Service for serving Pennsylvania and Upstate New York.

Tandem lift

Tandem lift to upright a contact tower for a natural gas dehydration unit. Mansfield Crane Service continuing to build and maintain midstream infrastructure in the Appalachian Basin.

Laying out rig mats

Laying out rig mats on a well site in the Marcellus/Utica play. Mansfield Crane Service 350-ton makes quick work of setting nearly 300 mats.

Lifting sector frames

Lifting sector frames onto a 300’ twin guyed tower. Cell tower sites can be the most remote and challenging job sites that Mansfield Crane Service accesses in Pennsylvania and Upstate New York. Using our 350-ton long boom crane makes this easier...

Lifting hollow core plank

Lifting hollow core plank onto a mezzanine inside a maintenance garage. Mansfield Crane Service 25-ton industrial carry deck crane fit into this constrained area and set forty five panels all in a single day. The difficult planks were located at...

lifting precast deck panels

Bridge work on a beautiful morning, the best part about construction is being outdoors and knowing the work you do is meaningful. Mansfield Crane Service lifting precast deck panels for a township road bridge replacement.

delivering jobs thought impossible

With less than six inches to spare of headroom. Hours of onsite measuring, and input into a model, resulted in Mansfield Crane Service delivering a job that others thought impossible.

Replacing utility poles

Replacing utility poles. We were setting and removing old equipment in a hard to reach job site.